Medical Assembly Platforms for Pens, Autoinjectors and Syringes.

Automediq enables medical innovation with scalable assembly platforms focused on safety, quality, and reliability. Our pre-assembled cell offers high availability, fast delivery, and easy retooling within GMP and CFR standards, ideal for cost-effective pilot production.

Safety

Proven concepts with a strong base and happy customers, meeting GMP/GAMP and CFR standards.

Flexibility

Fully customizable systems to fit specific needs, compliant up to clean room class 7.

Consistency

Standardized technology from manual to high-speed production, ensuring seamless integration.

Smart Design

Next-gen HMI with audit trail, process steps, warnings, and a small footprint for clean rooms.

Modularity & Scalability

Add new products or variants with a modular, scalable design, reusable for future needs.

Quality

Swiss-made from 316L stainless steel for premium quality and long-lasting performance.

Efficiency

Quick product changeovers for high efficiency, with ERP and production planning interfaces.

Service / Support

Worldwide ramp-up support from dedicated, experienced staff for smooth operations.

Automediq

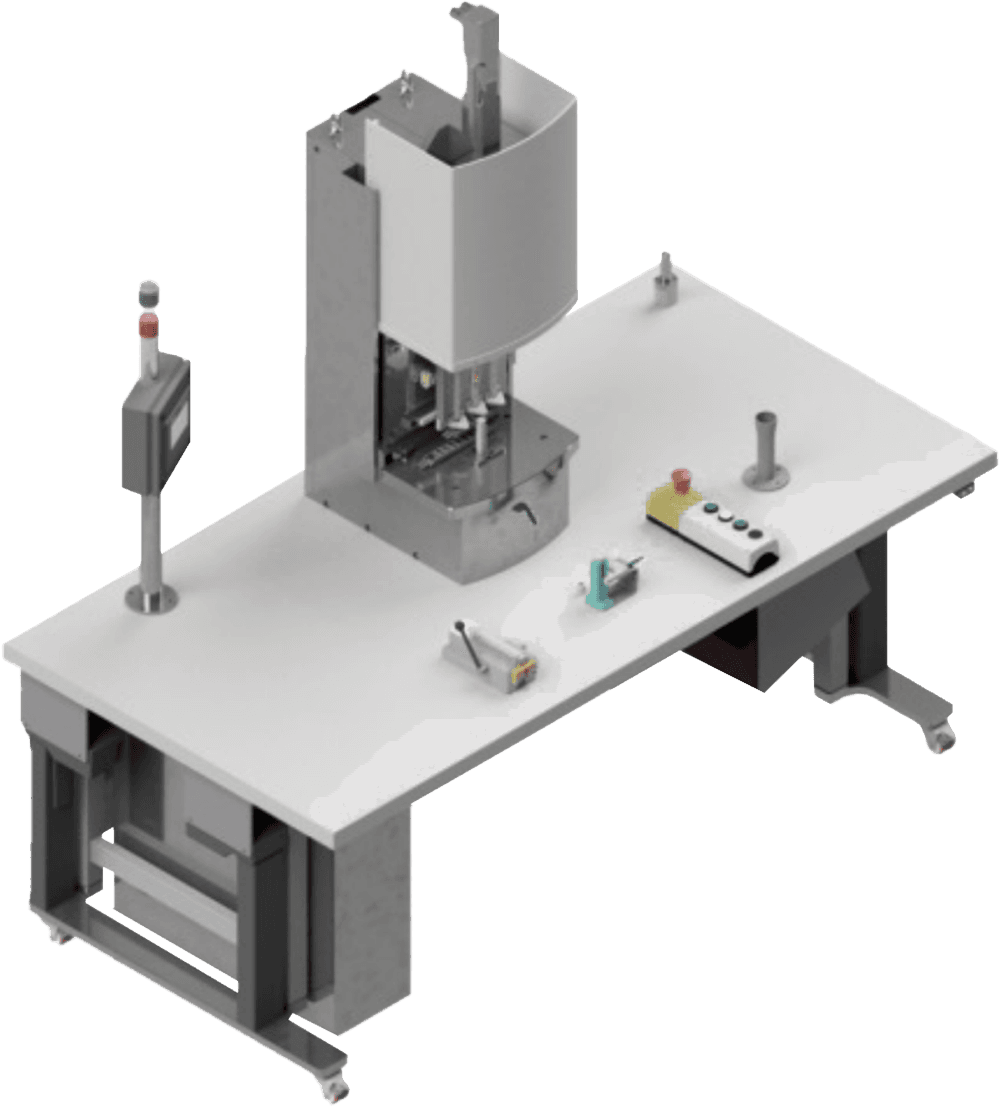

Lite

Output

90–180 parts p/h

Precision for small batches or laboratory production

Automediq Lite is designed for manual tasks, ideal for trials, clinical studies, stability tests, and small batches. Key processes like pressing, priming, and quality checks are automated, while loading and unloading is manual. Designed for one or two products.

Automediq

Cell

Output

600 parts p/h

Semi-automated efficiency

Automediq Cell seamlessly integrates manual loading with robotic handling to enhance assembly efficiency. This semi-automated system features automatic assembly, manual unloading of OK parts, and robot sorting for NOK parts, with options for quality checks, labeling, and packaging.

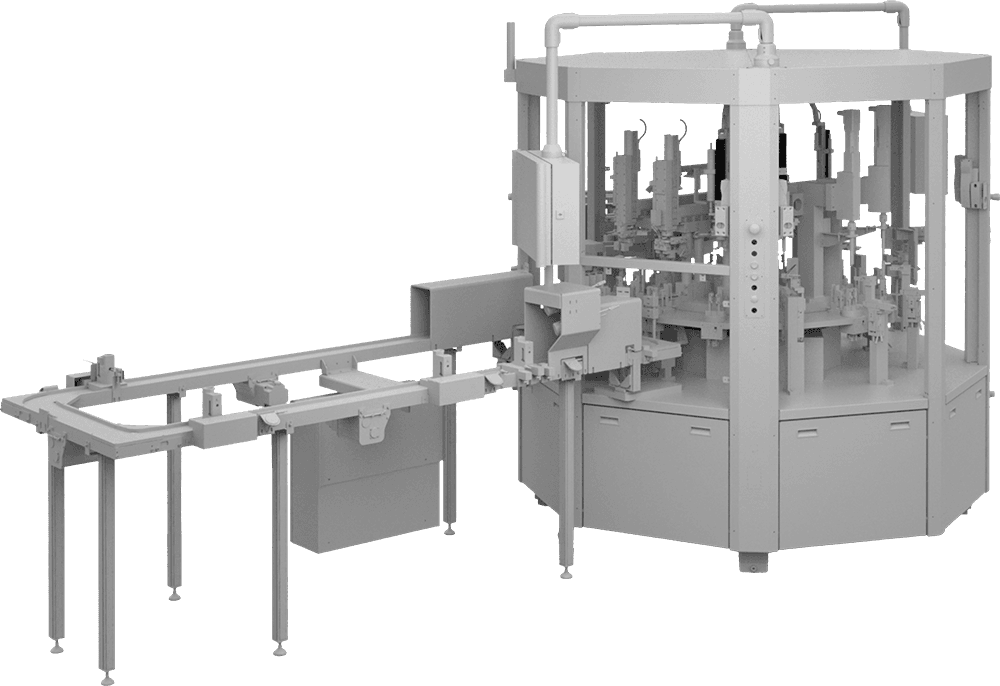

Automediq

Pro

Output

900 parts p/h

High-performance assembly

Automediq Pro supports high-volume production with semi or fully automated assembly capabilities. It offers the flexibility and efficiency needed for demanding environments, with manual or automated loading/unloading and quick retooling for 2–3 products.

Smart HMI

Next Generation HMI

Smart HMI provides an easy-to-use interface designed for Industry 4.0 and IoT. It enables seamless data exchange, integrates with ERP and SCADA systems, and features Batch Manager, Recipe Manager, and Audit Trail, ensuring efficient and compliant manufacturing processes.

Smart Extensions

Auto Labels and Cartooning

Labeling can be integrated in the base machine or placed as an add-on cell to your Automediq platform. Labeling with Termoprint or Laser printing. Packing and Cartooning is an add-on of well known packing solution providers based on your needs of tubular bags, blisters or boxes.

Partnership with BD Medical

At Automediq, we believe that cutting‑edge automation starts with the very best components. That’s why we work hand‑in‑hand with BD Medical, a world leader in injection and safety devices. Our modular production lines are fully engineered to mount and assemble three flagship BD formats:

BD Vystra™

Disposable Pen

BD Physioject™

Disposable Autoinjector

BD UltraSafe™

Passive Needle Guard

By integrating these trusted BD systems into our automated platforms, we deliver:

Seamless integration

of BD components for reliable, high‑speed assembly

Fully validated, GMP‑compliant processes

to meet regulatory and quality requirements

Scalable production

that grows with your needs, maximizing uptime and efficiency

Experience the synergy of BD’s proven device technology and Automediq’s automation expertise, bringing you streamlined workflows, consistent quality and the agility to lead in today’s parenteral delivery market.

Get in touch.

Contact us today for more information or to schedule a consultation.